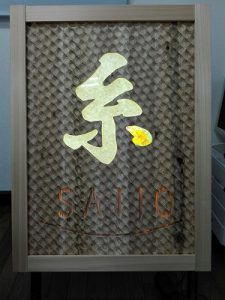

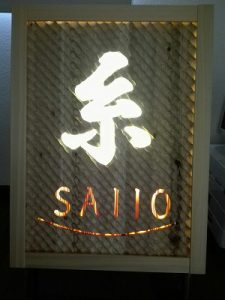

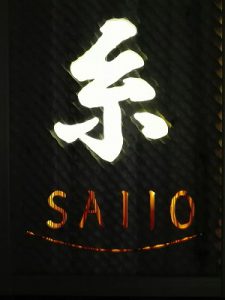

A wooden signboard illuminated by LED from the behind. We designed the surface with Naguri grooving and hollowing out 糸 â€کIto’ characterآ by 3D cad and it was crafted by a CNC machining centre.

We worked quite a lot of finishing tasks by hands after that. Finally, the signboard was exhibited in our booth during the design competition last Saturday.

آ

آ

آ

آ