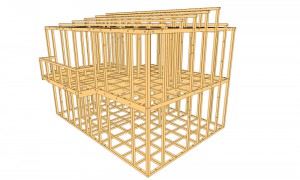

Main Structural Frame

The most common joinery system that is used to build both detached and semi-detached wooden frame houses are post-and-beam method called РђўZairaiРђЎ which is mostly crafted by fully automated machine-cut process in current Japanese market. ItРђЎs about 90 percent per annum of the total project.

We have equipped precut machines which produce main structural frames, sub structural frames, supportive components and sub-roof and sub-floor panel parts.

In order to reduce the cost of project, our dedicated machinery with the sophisticated CAD/CAM program minimise the lead time and material waste.

Joint system for Japanese post-and-beam frame is now available in two different methods, wood crafting joint and metal-fastener joint.

We provide the following type of components as main structural frames;

Column, Sill, Horizontal beam (girt, summer), Purlin, Brace.

Wood Crafting Joint

|

| click to enlarge |

Vertical posts (columns) and horizontal beams with diagonal bracing compose the main structure. Post and beams are joined by a crafted joint e.g. tenon, motise, and dovetail etc.

The origin of the method goes back to the eighth century and it was used for famous shrines such as Ise and Izumo, for instance.

Reference for crafted component

| click to enlarge | ||

|

|

|

|

|

|

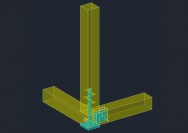

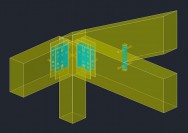

Pin-connected ( Metal-fastened ) Joint

Pin-connected joint is an alternative connection system for traditional wood crafting joint. It is a modern post-and-beam method using single or twin hanger plates, metal tubes and drift pins and often contrasted to Zairai method. It allows structural strength to be logically calculated by combination of Glulam and a certificated metal fitter in particular.

Recently, Japanese house buyers greatly consider earthquake-resistant structures. Thus the building method has become popular in the recent market.

┬аPerspective sectional drawings

| ┬аclick to enlarge | ||

|

|

|

┬аPopular type of connector

| click to enlarge | ||

|

|

|

| connection tube №╝І twin slot hunger | connection tube №╝І twin slot hunger | ‘single’ slot plate №╝І ‘single’ slot hunger |

| HSZ connecter┬а┬а┬а┬а┬а |

Creteck connecter |

Mokken connecter┬а┬а |

‘Hagara’ Sub-frame component

|

| click to enlarge |

We supply several types of sub-structural frames called РђўHagarazaiРђЎ as our standard components. The components we supply for are; rafter include hip, valley and fly rafter and ladder, fascia, studs, floor joist, window sill and trim. Both domestic and imported softwood spieces are available for the component.

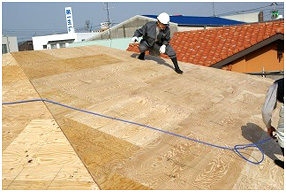

A benefit of pre-cut panel is to ease the on-site work. It is unsafe to measure and cut on purlin on the rafters in rising work. Safe work environment could make reduction of lead time.

┬аReference for crafted component

| click to enlarge | ||

|

|

|

Structural panel component

Two different components, sub-roofing panel and sub-flooring panel are in our product range.

Using structural plywood as sub-flooring and sub-roofing panel of the building is a great contribution to reinforce building stiffness against lateral distortion of earthquake and wind force.

|

| click to enlarge |

Standard size of plywood : W x L x T (mm)

– Sub-roofing panel: 910x1820x12

– Sub-flooring panel: 910x1820x24, 1000x2000x24

Reference for┬аcrafted component

| click to enlarge | ||

|

|

|

|

|

|